Moroccan Wood Furniture: A Trip Through Time and Craftsmanship (Part C)

The Art of Moroccan Woodworking: Materials and Making Process.

The story of Moroccan furniture history isn't just one of design. It's a tale of natural resources, centuries-old tools, skilled hands, and evolving technologies — all blending into what we now know as Moroccan handmade craftsmanship. This final part of our series explores the materials and processes used in the creation of this furniture, giving you a closer look at what brings each piece to life.

The Materials Behind Moroccan Wood Furniture

In Moroccan woodworking, it all starts with one critical element: the wood.

Cedar Wood – The Heart of Moroccan Craftsmanship

Cedar is the most beloved and widely used wood in Moroccan furniture making. Native to the Middle Atlas Mountains, Moroccan cedar is prized for its fragrance, natural resistance to insects, and warm hue. Beyond its beauty and durability, cedar holds cultural importance, particularly in Fez and Marrakesh, where many craftsmen still source it locally.

It’s often the default choice for carved tables, panels, and traditional cabinetry.

Thuya (Native – Rare):

Known for its dense grain and aromatic quality, thuya is sourced from the Essaouira region and often used in decorative objects like boxes, chests, and accents.

Orange Wood (Native – Common):

Commonly used in small decorative items, known for its fragrance and fine texture.

Walnut (Native – Rare):

A strong and refined wood, often chosen for its elegant texture and long-lasting durability.

Red Wood (Native – Common):

Characterized by deep reddish hues, this wood is often used in contrast-heavy design.

Supporting Materials That Define Moroccan Aesthetics

What makes Moroccan wood furniture truly stand out is the way wood is enhanced by other natural and crafted elements. These include:

Brass & Wrought Iron:

For structural support, engraved ornamentation, or artistic hardware.

Zellige Tiles & Marble:

For tabletops and decorative details.

Bone and Mother-of-Pearl:

Featured in inlay work, creating stunning visual contrasts.

Many Moroccan artisans have shifted toward sustainable practices by sourcing local, eco-friendly materials. Reclaimed wood and sustainable forestry have become common in workshops across the country.

The more local we go, the stronger the story the piece will tell.– a saying among cedar carvers in the old Medina of Fez.

Traditional and Modern Making Process:

Once the right materials are chosen, the furniture enters its second stage: transformation.

1. Shaping and Assembly

Each project begins with shaping wood into slabs, beams, or legs depending on the function of the piece. Clients may ask for a carved cedar coffee table, a low Berber Mida, or a complex panel — and the workshop adapts accordingly.

While some basic cutting and smoothing may use electric saws or sanders, the true shaping is done with vintage chisels and hand tools passed from father to son.

2. Carving by Hand

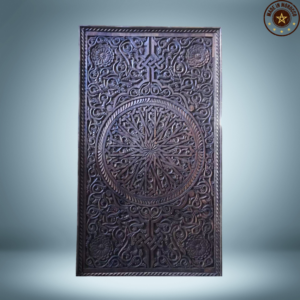

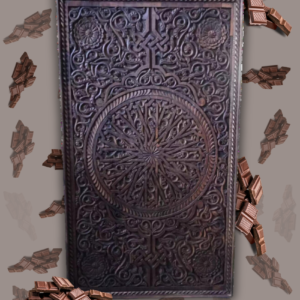

This is where the artisan’s personality takes over. Using traditional motifs like Amazigh symbols, floral Andalusian flourishes, or sacred geometry, carvers bring the wood to life.

Designs are carefully measured and etched in stages, with master craftsmen sometimes spending weeks on a single intricate table surface.

3. Decorative Finishing:

Depending on the design, the piece may then be handed off to:

A painter, who adorns it with vibrant colors and patterns.

A metalworker, who adds iron or brass handles and corner details.

A leatherworker, who integrates pouf tops or inlays for seating.

In many medina workshops, these stages are carried out under one roof in quiet collaboration — painter next to carver, next to welder.

4. Modern Additions to Traditional Craft

While hand tools are still central to Moroccan craftsmanship, some artisans have welcomed CNC carving for pre-design and CAD software for measurements.

This tech-meets-tradition model allows for large-scale orders while maintaining the unique imperfections that define handmade Moroccan furniture.

Preserving and Evolving a Living Heritage:

Each piece of Moroccan furniture is a timeline in wood — from Berber simplicity to Moorish detail, from cedar roots to mother-of-pearl blossoms.

Whether it's a low Amazigh Mida or an Andalusian wall panel, the furniture remains a symbol of place, people, and passage.

In our next blog post, we’ll explore the various furniture styles by name and design family — from Berber Amazigh and Andalusian to fusion pieces seen in modern Moroccan homes.

PS: Everything featured in this post — from cedar-carved tables to inlaid panels — is something we can create. Just send us an image or idea, and we’ll help turn your vision into a handmade piece. Fill out the form here to begin.

Hot This Week

Explore our collection

Octagonal Moroccan Carved Table/ Andalusian Style

Moroccan Hand Carved Dinning Table/ Geometric Lining design / Andalusian style

Moroccan Carved Table /Floral motif/ Andalusian style.

Set of 3 Moroccan Brass Coffee Tables/ Andalusian Style.

Moroccan Wall Carved Panel/ Floral motif / Andalusian Style.

FAQ

Cedar is the most common and traditional wood used due to its durability, scent, and carving quality.

Yes, while some parts are now assisted with machines, much of Moroccan furniture is still handcrafted using tools passed through generations.

Depending on the level of carving and materials, it can take between one to four weeks.

It’s the fusion of materials — from carved wood to zellige, brass, and bone — plus the storytelling in its patterns and craftsmanship.

14 comments

Leave a Comment Cancel reply

Post Categories

- All

- Carving & Painting Techniques

- Cultural Travel in Morocco

- Culture and Society

- Handicrafts & Techniques

- Home Improvement

- Interior Design Inspiration

- Leather & Tannery Traditions

- Moroccan Coffee Tables

- Moroccan Furniture

- Places to Visit

- Travel

- Zellige Tile & Mosaic

Andre M

April 1, 2025 at 6:09 pmI’ve been looking for real Moroccan furniture for my apartment and most of what I find feels mass-produced. This post opened my eyes to what handmade really means. Big respect to your family and the artisans.

Hassan boutabaa

May 27, 2025 at 1:48 amThank you, Andre — really appreciate that. It means a lot coming from someone who’s taking the time to look beyond the surface. If you ever want help picking a piece that tells a story, we’re here.

Nora G

April 6, 2025 at 2:04 pmI do wood carving as a hobby and this post really made me appreciate the level of dedication Moroccan artisans have. That fusion of old and new is magic.”

Hassan boutabaa

May 27, 2025 at 1:44 amNora, that’s amazing to hear! You totally get it. It’s a beautiful blend. would love to see your work sometime!

Daniel W

April 7, 2025 at 1:15 pmStumbled across this post by accident and couldn’t stop reading. The part about artisans passing down chisels through generations gave me chills.

Hassan boutabaa

May 27, 2025 at 1:42 amDaniel, that’s one of my favorite parts too. Glad it moved you.

Sofia Malik

April 13, 2025 at 1:24 amBeen following your blog since the ‘Part A’ post. Loved seeing how you talked about combining metals, bone, and wood here. It’s such a rich tradition.

Hassan boutabaa

May 27, 2025 at 1:40 amSofia! Thank you for sticking with the full series — it means a lot.

Léa C

April 16, 2025 at 6:40 amI found this while searching for traditional Moroccan furniture styles. Your writing made me feel like I was right there watching the process. Very inspiring!

Hassan boutabaa

May 27, 2025 at 1:38 amMerci Léa — your words mean a lot.Thanks!

Jason R

April 19, 2025 at 4:24 pmI remember you mentioned this when I ordered my panel last fall — cool to see the full breakdown now. That section about Thuya wood is spot on!

Hassan boutabaa

May 27, 2025 at 1:37 amHey Jason! Always great to see a familiar name here — glad you recognized the details. Hope your panel is still glowing strong at home. Thanks again for supporting handmade craft!

Jamesamide

April 23, 2025 at 8:23 amThis was so beautifully written. I had no idea cedar wood played such a big role in Moroccan furniture. Learned something new today!

Hassan boutabaa

May 27, 2025 at 1:35 amThank you, James! I’m so glad you found it helpful.